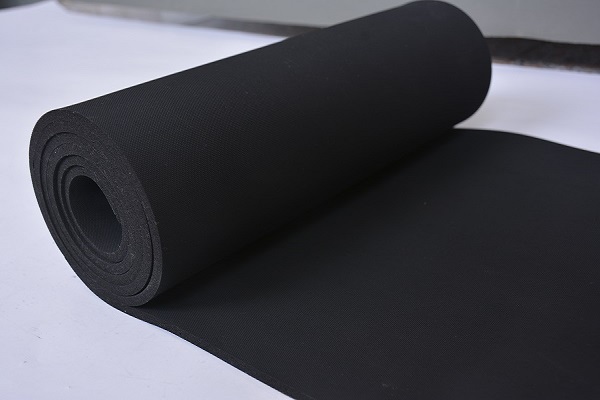

In today’s rapidly developing industrial and urbanized era, vibration and noise pollution have become issues that cannot be ignored. Vibration isolation rubber pads, as a highly efficient vibration isolation material, are widely used in various fields due to their unique elasticity and vibration isolation performance, ranging from industrial machinery to household appliances, as well as transportation and construction engineering. This article will delve into the installation methods of vibration isolation rubber pads and their significant roles in different fields.

The installation steps of vibration isolation rubber pads mainly include the following:

1. Cleaning the base ground: Thoroughly clean the installation ground with a cleaner or water to ensure there is no dust, oil stains, or other debris. This step is crucial because any tiny impurities may prevent the rubber pad from fully adhering to the ground, affecting the vibration isolation effect.

2. Backing metal plate: Some rubber vibration isolation pads require a metal plate as a support before installation. According to design requirements, the metal plate should be placed in the designated position and fixed to ensure its stability.

3. Placing the rubber pad: Place the rubber vibration isolation pad on the metal plate or directly on the cleaned ground, ensuring it is fully in contact with the supporting surface. To further secure the rubber pad, it can be firmly installed on the ground using glue or bolts as per design requirements.

4. Structural connection: If it is necessary to connect to other structures or equipment, fix it using bolts, steel plates, etc. This step ensures that the rubber pad is tightly connected to the structure to be isolated, fully exerting its vibration isolation effect.

5. Inspection and testing: After installation, carefully check if the rubber pad is firmly fixed and free from deformation or damage. Before actual use, the vibration isolation effect of the rubber pad can be tested by applying force or vibration to ensure it meets the expected performance standards.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, Neoprene Rubber Sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.

⊗Language | sitemap | privacy Policy

Copyright © 2025 Dongfang Chemical Co., Ltd. (DFCC)- www.siluzan.com All Rights Reserved.