在现代工业和日常生活中, rubber products play an indispensable role. They are widely used in various fields such as construction, machinery manufacturing, electronics and electrical appliances, and personal protection. 他们之中, anti-vibration rubber sheets and silicone rubber sheets, as two common types of rubber materials, have attracted much attention due to their unique properties. This article will delve into the differences between these two materials and analyze their advantages in different scenarios.

1. Composition of rubber sheets

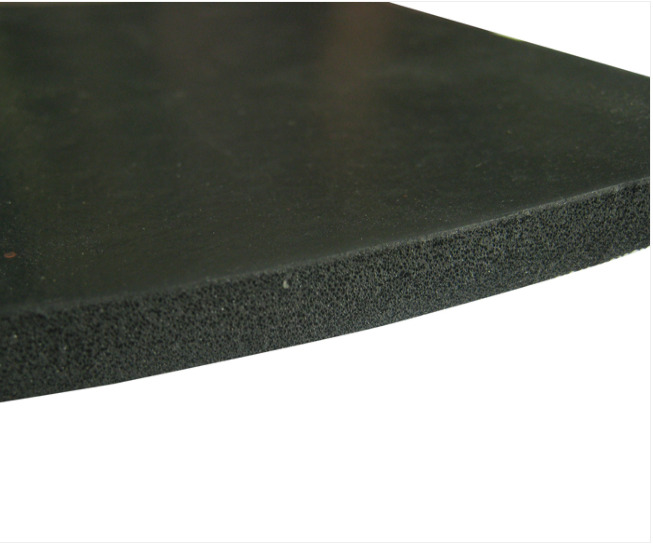

Anti-vibration rubber sheets, 顾名思义, are rubber products with a vibration-absorbing function. They are usually made of natural rubber or synthetic rubber and improved by adding fillers such as carbon black and sulfur to enhance their wear resistance and elasticity. The main feature of this material is its ability to effectively absorb and disperse vibration energy, reducing noise and vibration generated by machinery equipment and protecting equipment from damage.

Silicone rubber is a high-performance synthetic rubber made of siloxane polymers, with excellent temperature stability and chemical inertness. This means that silicone rubber sheets can work in extreme temperature conditions and show good resistance to most chemicals. 此外, it has good electrical insulation properties, making it an ideal choice for the electronics and electrical appliances industry.

2. Performance differences

Differences in Thermal Resistance Performance

Although rubber anti-vibration pads have certain thermal resistance, they tend to age and lose elasticity in high-temperature environments. 相比之下, silicone rubber pads can maintain their physical properties unchanged within the temperature range of – 60°C to + 250°C, making them suitable for applications that require resistance to high or low temperatures.

Differences in Chemical Resistance

The presence of silicon-oxygen bonds in the molecular structure of silicone rubber makes it resistant to the corrosion of a wide range of chemicals, 包括酸, 基地, 油, and solvents. This is particularly important for the chemical industry, as many chemical reactions take place in corrosive environments.

Differences in Electrical Insulation Performance

Silicone rubber pads are often used as insulation layers for electrical wires and cables due to their excellent electrical properties, especially in high-voltage environments. Traditional rubber anti-vibration pads also have some insulation capabilities, but they are still inferior to silicone rubber in this regard.

⊗Language | sitemap | privacy Policy

Copyright © 2025 Dongfang Chemical Co., 有限公司. (DFCC)- www.siluzan.com All Rights Reserved.